Useful and reliable software support is essential for smooth cooperation with your suppliers. This is the only way to make your supplier management efficient. The tsm enterprise solution offers you the basis for this. It provides you with the tools you need to improve structures and processes in the supply chain as well as in your own company in the long term.

With the tsm enterprise solution, you can take a holistic, preventive and cross-functional approach to optimizing your supply chains. Important information is collected, evaluated and is available to all relevant departments in your company.

Even you can increase communication and coordination in your company and act as a unit in front of every supplier – with the tsm enterprise solution.

Optimize your supply chains with the tsm-workflow

The entire supply chain is checked for supply risks using hard and soft facts. The knowledge about future supplier performance is predicted. This forms the basis for preventive options for action.

Based on the knowledge generated, a cross-functional steering committee makes transparent and coordinated decisions that ensure that supply risks are avoided or minimized at an early stage.

Supplier projects decided upon by the steering committee follow an experience-based, standardized procedure and can be tracked at any time with regard to their progress.

Suggestions for improvement in supplier management are systematically derived from the supplier projects carried out in order to ensure the prerequisites at the interface to the supplier base.

The tsm enterprise solution is based on 20 years of experience in practice, science and consulting. Accordingly, the tsm-workflow is adapted to the daily processes and tasks. For this purpose, the required methods and tools are made available to you.

The individual methods and tools are organized along the tsm-workflow. This way, no data is lost and you always keep everything in view.

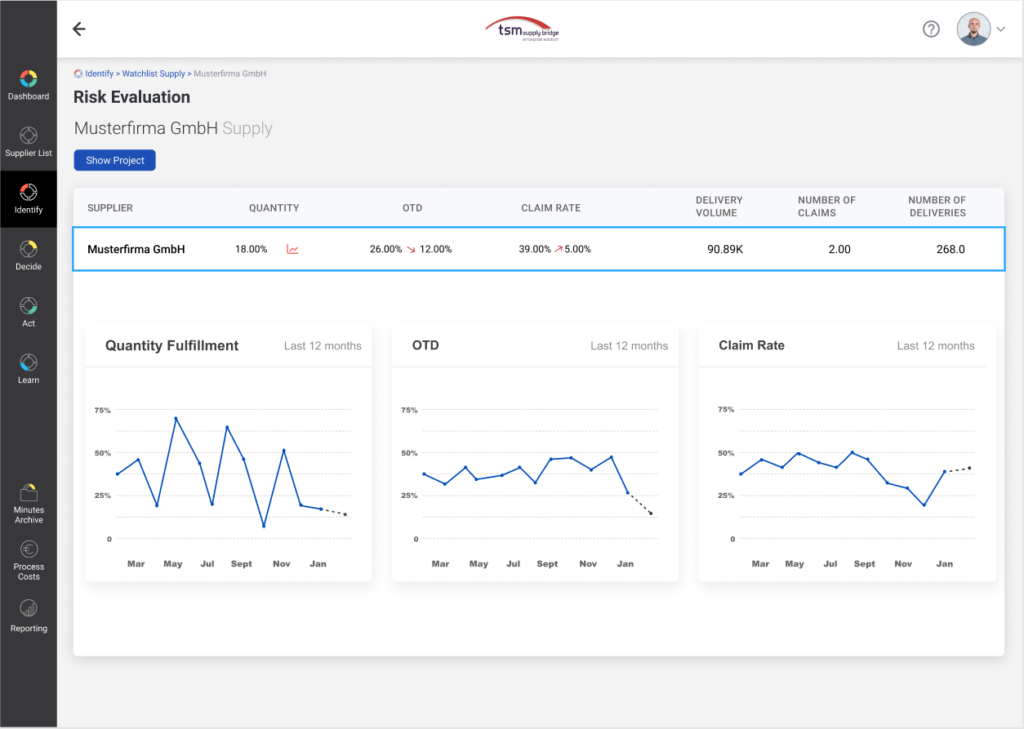

Identify

Use trend and prognosis models to predict possible incidents. This is done both generally for all suppliers and at the level of each individual supplier.

This allows you to identify risks at an early stage and minimize them reliably.

Consider all supplier-specific process costs of your company, which result from the performance of your suppliers. This allows you to draw important conclusions about the business impact of an incident in the supply chain and initiate efficient countermeasures in good time.

Find critical suppliers with intelligent analysis methods. Datamining methods search for anomalies in your database, allowing you to identify supply risks that would have remained undetected with conventional methods.

Use our tool to regularly check the data quality of your key figures. In this way, you can ensure even more precise analyses and forecasts and more reliable decision-making processes.

Gain a 360° view of individual suppliers through the central supplier file where all information and history of each supplier is stored.

The tsm command center, in which all important data and key figures are clearly arranged and can be viewed by management at any time. Always have the tsm-workflow and all important information about your supplier network in view!

In many cases, there is not only a single risk for incidents within the supply chain. It is rather the interaction of several risks that endangers your supply chains. Multi Risk Management gives you an overview of all risks and how they relate to each other and influence the supply chain.

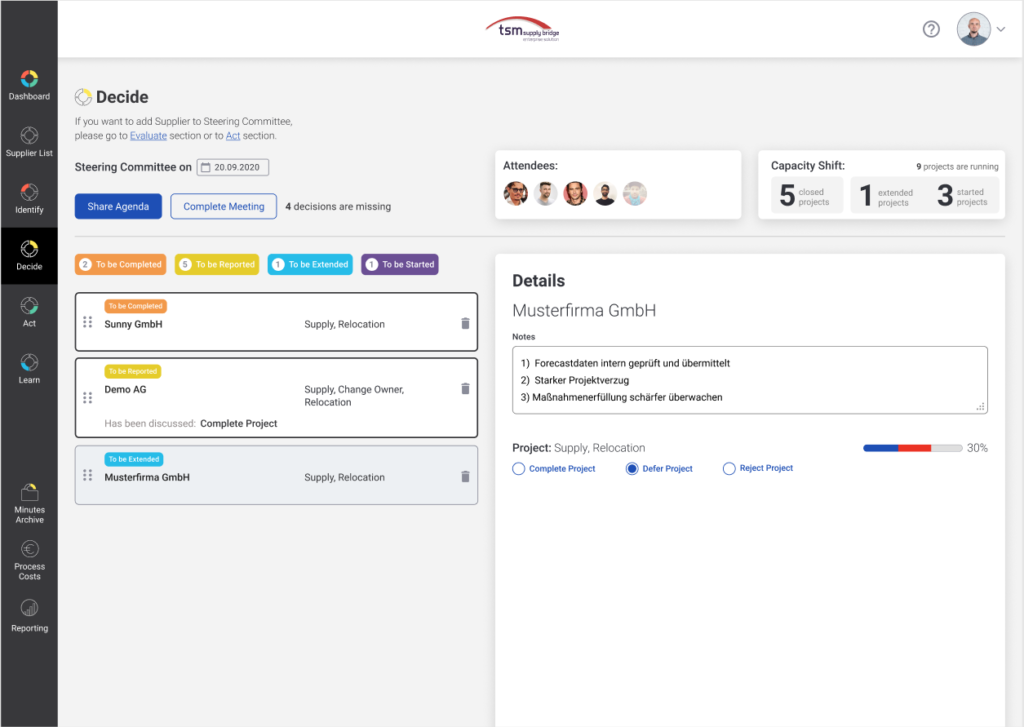

Decide

The Supplier Steering Committee is a cross-functional board in which all affected departments meet regularly. On the basis of a standardized escalation model, situation-specific and efficient measures to restore or increase the supplier performance are decided jointly. In this way, you achieve a coordinated and efficient approach to suppliers.

Create a detailed report for each supplier that contains all relevant data for initiating and tracking supplier projects. In this way, existing supplier development resources can be coordinated efficiently and transparently.

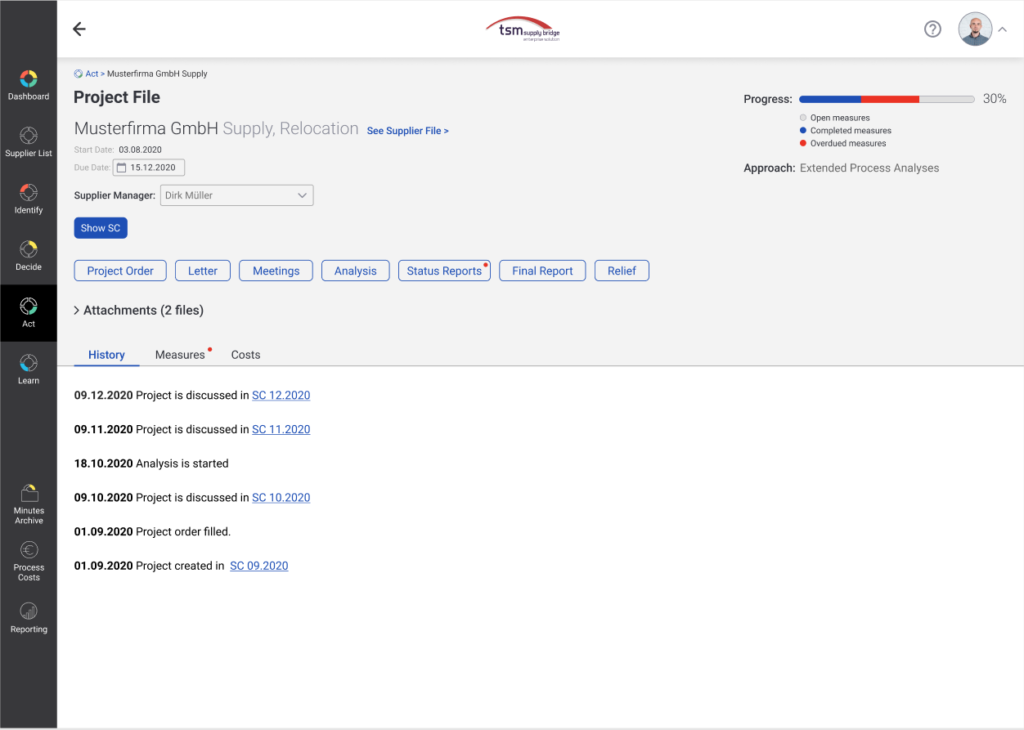

Act

Successful supplier projects are based on a standardized, proven approach and toolbox. A process analysis with all affected departments guarantees an efficient and sustainable problem solution.

Using a standardized analysis procedure, the incidents along the supply chain are identified for all affected departments. By means of a structured evaluation, the measures can be prioritized and implemented sustainably with the suppliers and in the own company.

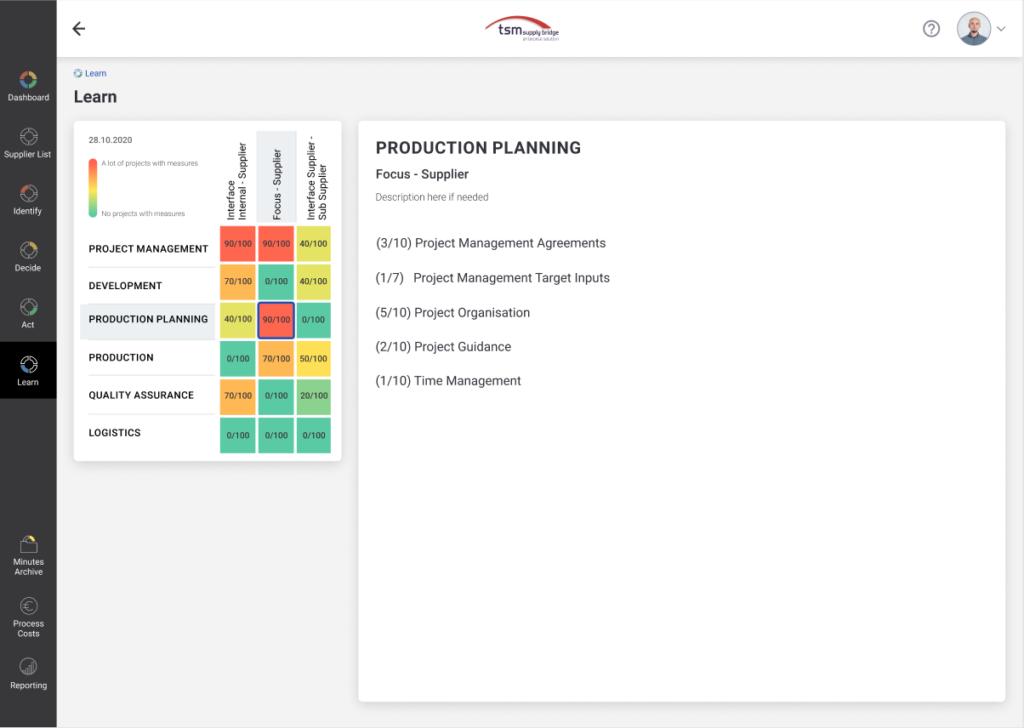

Lessons Learned

On the basis of the supplier projects carried out, a consolidated presentation of weak points in the company’s own processes is presented. Process and cost advantages can be systematically derived from these interface deficits between company and supplier. In this way, you can constantly work on optimizing internal processes in your company.

With the tsm enterprise solution, your company can act in a strong and coordinated manner

The tsm enterprise solution makes everyday work easier for you and your company. Relevant data is collected and evaluated in a smart way. This makes processes much more efficient and no information is lost.

Would you also like to approach your supplier management holistically, preventively and cross-functionally? Contact us and we will support you in the introduction of the tsm enterprise solution in your company.

Contact

Phone: +49 30 74696537-0

E-Mail: info@tsm.berlin

Silberburgstr. 143

70176 Stuttgart